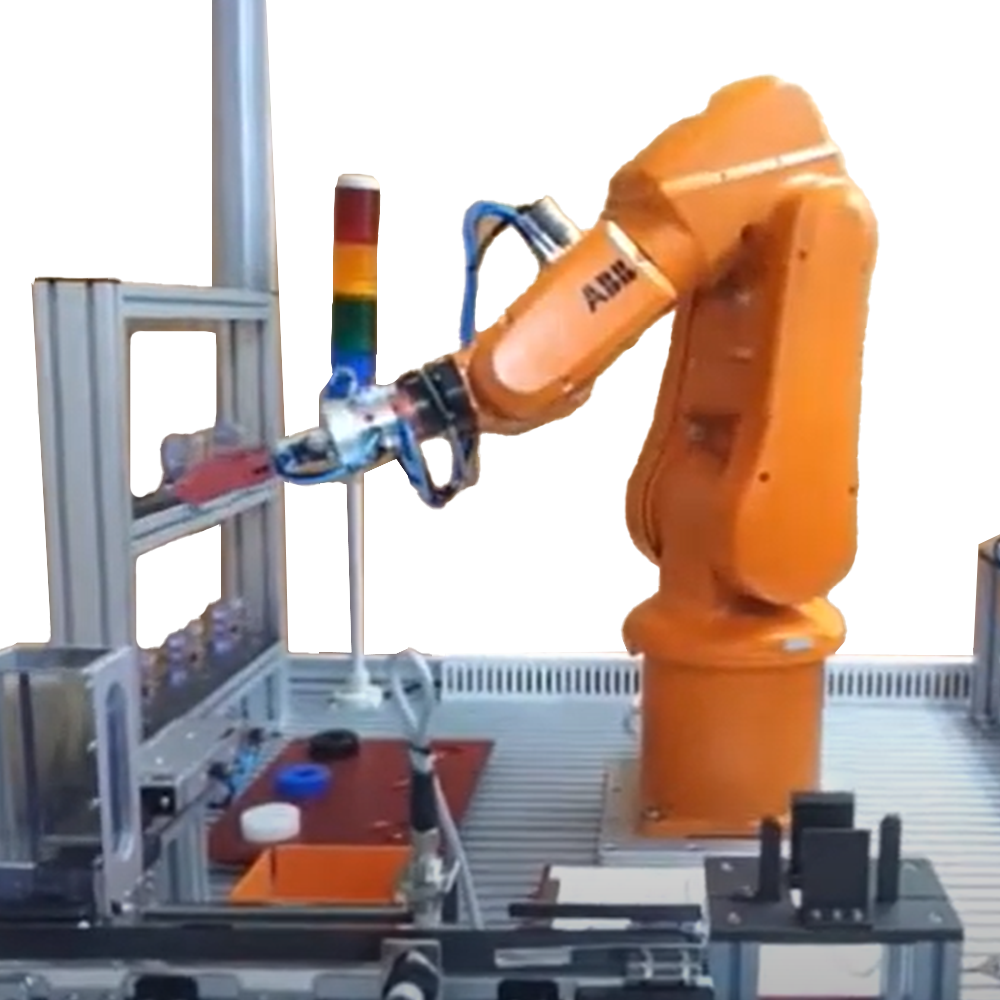

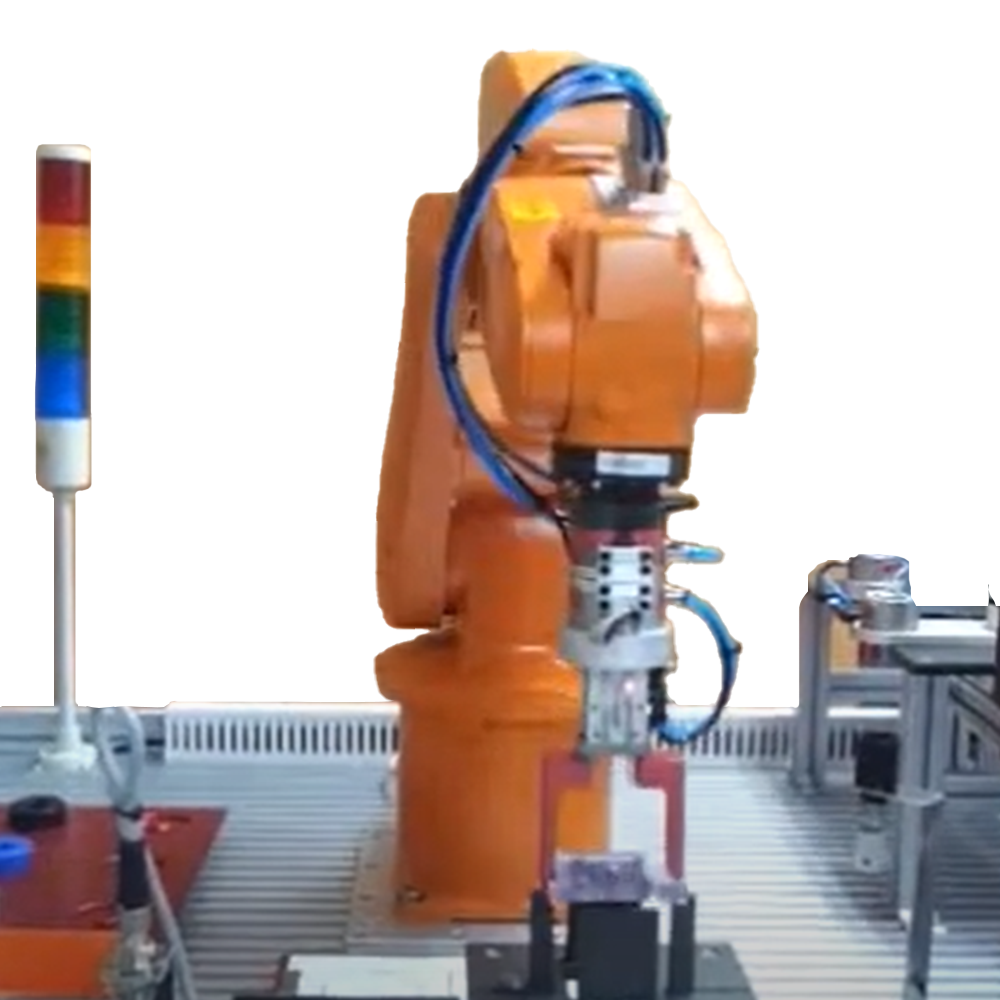

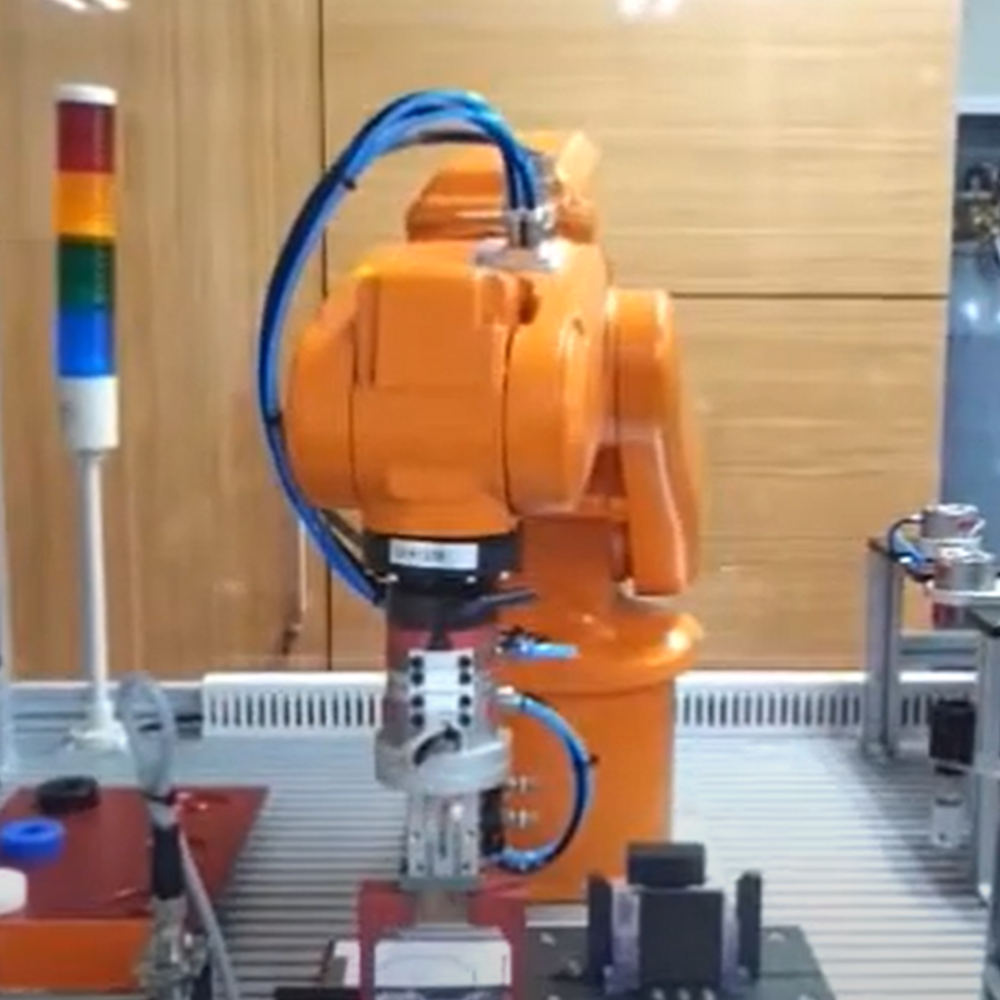

6-Axis Robot Trainer

-

Payment

T/T

-

MOQ

1 ea

-

Supply Ability

9,999,999 ea per One-Time

-

Supply Details

Customization

Negotiable

-

Country of sale

Asia, Middle East, Europe, Africa, World Wide

-

PRICE

-

FOB

USD 50,000.00 ~ 100,000.00

(1 ea)

-

ITEM SPECIFICS

-

Brand

Model IEG 2211IEG Co., Ltd.

-

origin

Republic of Korea

-

Size(Capacity)

Customized

-

Function

For practicing how to operate 6 - Axis Robot Trainer

-

Material

Metal

-

Color

Orange

-

age-appropriate

Adults

PRODUCT DESCRIPTION

6-Axis Robot Trainer

Key Features

· 6-Axis Vertical Articulated Robot:

Offers high flexibility and precision with a reach of 580 mm+, payload of 3 kg+, and repeatability of ±0.01 mm.

· Compact & Lightweight:

Weighs only 25 kg with a small 180 mm² footprint—ideal for training labs or compact automation cells.

· Integrated Fuel Cell Assembly System:

Includes conveyors, inspection sensors, stacking modules, and storage—simulating a real-world production line.

· Auto Tool Changer:

Enables the robot to switch between tools (gripper, pen, drill) automatically using pneumatic and electrical connections.

· Advanced Control System:

Includes a multi-processor controller, Flex Pendant with touchscreen, and support for various fieldbus protocols (PROFINET, DeviceNet, etc.).

· Simulation & Offline Programming:

Comes with a virtual robot environment for safe, pre-deployment testing and layout optimization.

· Vision Inspection System:

Built-in camera and image processing for shape, color, and edge detection—great for quality control training.

Advantages

· Hands-On Learning:

Perfect for education and R&D, allowing students or engineers to practice real-world automation tasks.

· Modular & Expandable:

Includes multiple modules (conveyor, inspection, stacking) that can be reconfigured or upgraded.

· Realistic Industrial Environment:

Mimics actual production lines, including I/O wiring, pneumatic control, and vision inspection.

· Safety & Accessibility:

Transparent enclosure and IP30 rating ensure safe operation in classroom or lab settings.

· Multi-Tool Capability:

With interchangeable end-effectors, it supports diverse applications like pick-and-place, writing, and drilling.

How to Use It

· Programming: Use the Flex Pendant or offline simulator to teach positions and write control logic (e.g., pick, place, inspect).

· Tool Setup: Attach the desired tool (gripper, pen, drill) using the auto tool changer.

· Material Handling: Load components into the supply station; the robot will pick, inspect, and stack them using the conveyor and sensors.

· Inspection: The vision system checks for defects or alignment before stacking.

· Monitoring & Feedback: Use the HMI and I/O modules to monitor status, control actuators, and log data.

· Tool Setup: Attach the desired tool (gripper, pen, drill) using the auto tool changer.

· Material Handling: Load components into the supply station; the robot will pick, inspect, and stack them using the conveyor and sensors.

· Inspection: The vision system checks for defects or alignment before stacking.

· Monitoring & Feedback: Use the HMI and I/O modules to monitor status, control actuators, and log data.

Specifications

| Product Name | 6-Axis Robot Trainer |

| Brand Name | IEG Co., Ltd. |

| Weight | About 100 ~ 300kg |

| Height | About 1.2 ~ 2m |

| Width | About 0.5 ~ 1m |

| Origin | Republic of Korea |

About Us

∙ Company Overview

IEG Co., Ltd. is a Korean-based manufacturer specializing in industrial education equipment and automation training systems. We innovate hands-on learning platforms combining robotics, PLC control, hydraulics, and mechatronics technologies.

∙ Factory Information

Our facility in Seongnam, Gyeonggi-do houses advanced production lines for precision assembly and system integration.

∙ Our Service

We offer customized trainers for universities and technical institutions, including curriculum design and installation support.

∙ Our Policy

IEG is committed to excellence in engineering, safety compliance, and educational empowerment through smart, scalable solutions.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Kim Chang il

SHIPPING

Shipping from :

Republic of Korea

- 7 Sunhwan-ro 198beon-gil Jungwon-gu (13204)

- Air Cargo : Please contact us for inquiry on carriers

- Sea Freight : Please contact us for carriers inquiry

- Land Transportation

- Air Cargo : DHL Impossible

- Sea Freight : impossible

- Please contact your administrator for detailed information.

- Name : Kelly,Cho

- Tel : 82-031-698-2210

IEG Co., Ltd.

The person in charge

CHANG IL KIMAddress

7 Sunhwan-ro 198beon-gil Jungwon-gu, Seongnam-si, Gyeonggi-do (13204)

HOMEPAGE

IEG Co., Ltd.

Introduction

IEG Co., Ltd. is a Korean-based manufacturer specializing in industrial education equipment and automation training systems. We innovate hands-on learning platforms combining robotics, PLC control, hydraulics, and mechatronics technologies.

Factory Information

Our facility in Seongnam, Gyeonggi-do houses advanced production lines for precision assembly and system integration.

Our Services

We offer customized trainers for universities and technical institutions, including curriculum design and installation support.

Our Policy

IEG is committed to excellence in engineering, safety compliance, and educational empowerment through smart, scalable solutions.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Smart Manufactuing/AI/IoT/VR/AR

-

- Established :

- 2009-03-01

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 51~100 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 61

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- IEG Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★